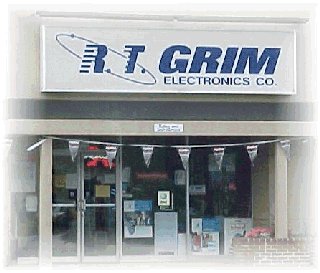

717-761-4113

3925 Trindle Road

Camp Hill, PA. 17011

Get Directions from Google

Hours of Operation:

Monday – Friday – 8:30 AM to 5:00 PM

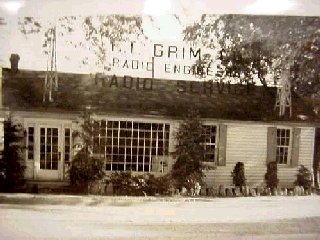

R.T. Grim Electronics was founded in September 1928 in Camp Hill, Pennsylvania when Russel T. Grim and his brothers opened a radio sales and service business. In 1928, the Great Depression took the wind out of sales and R.T. Grim Electronics focused on radio service and radio parts (tubes, etc.) sales. After World War II, the company became involved in a new national craze – radios installed in automobiles. Then came the next milestone in electronics, the introduction of black and white television. The company has continued to expand into the sales of automotive electronics and servicing of many of the new electronic technologies that have come along since then.

|